Action Priority Fmea

The team can use the Risk Priority Number to prioritize and reduce risks in the two following methods. The course is interactive with video audio illustrations and downloadable templates and charts.

This is the calculation of risk of a particular failure mode and is determined by the following calculation.

. The Institute for Healthcare Improvement has developed and adapted tools to help organizations accelerate improvement. The combined impact of these three factors is the Risk Priority Number RPN. FMEA is not a superhero.

Fill in a pre-made and flexible FMEA template using shapes arrows and colorful sticky notes to capture and organize your thoughts and arguments. 1 Successfully executing an FMEA takes up resources to complete. FMEA is a systematic proactive method for identifying potential risks and their impact.

Prioritize product or process deficiencies visually to gain the best results and satisfy your customers needs. The Actions that were previously determined in Paths 1 2 or 3 are assigned a Risk Priority Number RPN for action follow-up. The process is not without its issues.

RPN SEV x OCC x DET. FMEA is used during design to prevent failures. SOUTHFIELD Michigan June 03 2019 The Automotive Industry Action Group AIAG has collaborated with the German Association.

A poor detection ranking will drive an action to improve the ability to detect a cause of failure and warn of impending failure. New Form Sheets spreadsheet users and Software Report Views software users. Risk Priority Numbers RPNs Criticality Analysis FMEA with Criticality Analysis FMECA.

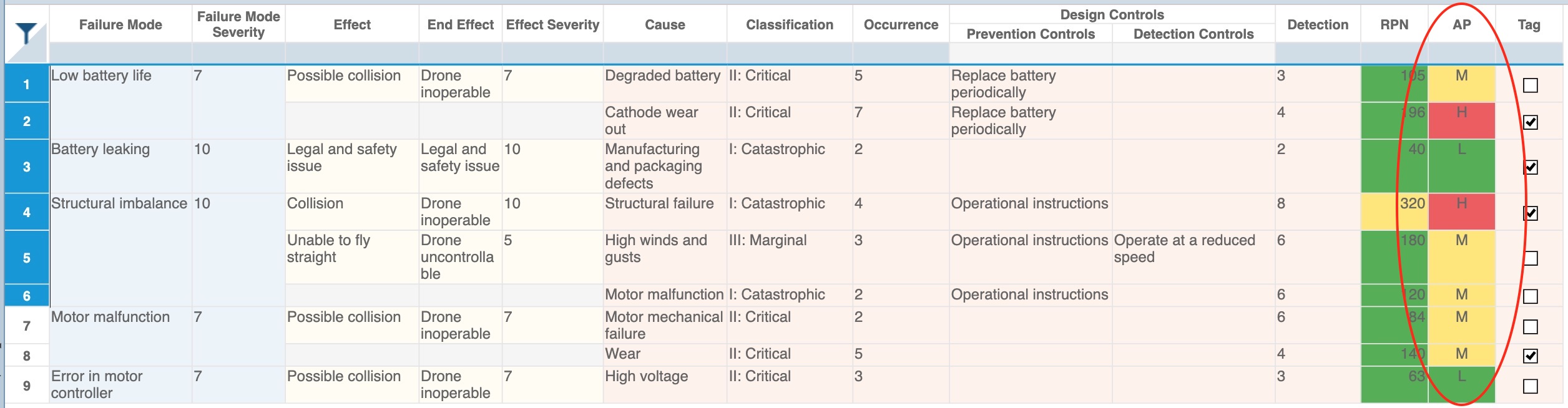

Rows can be filtered on Action Priority andor RPN. RPN may not play an important role in the choice of an action against failure modes but will help in indicating the threshold values for determining the areas of greatest concentration. Calculate your risk priority number RPN.

His main concern was the medicinal properties of opium Clark. When to use them and how. The purpose of the FMEA is to take actions to eliminate or reduce failures starting with the highest-priority ones.

Process guides the practitioner in aligning information between the steps to ensure accuracy and completeness of the FMEA. Learn to execute Design FMEA according the new handbook by achieving a deeper understanding of the explicit and subtle changes along with high impact benefits that will bring your organizations. FMEA is a qualitative and systematic tool usually created within a spreadsheet to help practitioners anticipate what might go wrong with a product or process.

It helps identify and assign priority to actions aimed to reduce risk while considering. Through curiosity Serturner got interested in the opium medicinal plant which was used by 18th-century physicians. The employer may use the business plan for emergency response submitted pursuant to subdivision a of Section 255035 and subdivision b of Section 25505 of the Health and Safety Code to the extent that the.

Includes Process Flow Diagram and Control Plan also. Report incomplete actions in any FMEA in an open action list and directly access the. Origin and Biochemical Basis for the Therapeutic Action of Morphine.

Use this download link to download and install the FMEA Studio add-in for Excel then open Excel and click on New Document to access the FMEA templates. When the assignee completes or changes the status of an action FMEA teams will also receive a notification. The RPN can be used to prioritize high-risk issues and determine the requirement for corrective action.

The RPN is used to place a priority on which items need additional quality planning. In other words a failure mode with a high RPN number should be given the highest priority in the analysis and corrective action. Basic Analysis Procedure for FMEA or FMECA.

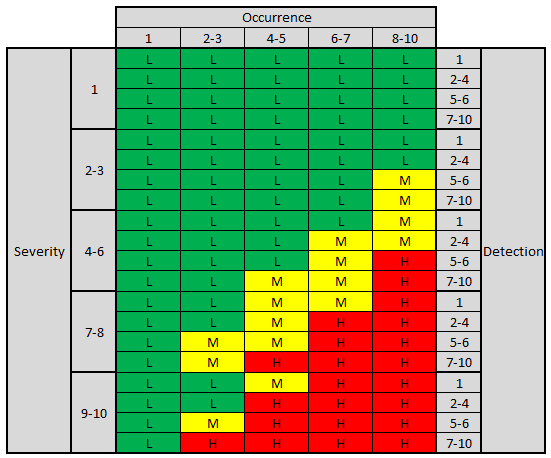

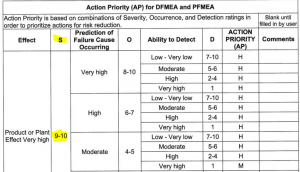

After calculation most companies prioritize risks from the highest to the lowest RPN. The AP provides a priority level based on Severity Occurrence and Detection values. In addition to identifying how a product or process might fail and the effects of that failure FMEA also helps find the possible causes of failures and the likelihood of failures being.

The Action Priority AP methodology and Tables to replace RPN. The employer shall establish and implement an Emergency Action Plan in accordance with the provisions of Section 3220. 31 FMEA RPN Threshold.

The FMEA Online Overview follows a structured approach for identifying and prioritizing potential failure modes taking action to prevent and detect failure modes andor causes of failure. RPN is calculated by multiplying the Severity Occurrence and Detection Rankings for each potential failure. Anticipating failures is the first step in being prepared for them or even creating an action plan to prevent them altogether.

While the RPN Risk Priority Number is a risk assessment value based on Severity x Occurrence x Detection AP was developed in. Design FMEA AIAG Process FMEA AIAG PFMEA Package AIAG. Overview of Risk Priority Numbers.

The detection ranking determines the effectiveness of the machinery and diagnostics controls. As soon as high-risk failure modes are identified FMEA teams can create an action within the app and its assignee will receive a notification containing the details of the corrective action due date and priority. There are commonly 3 key issues with FMEA each can be overcome with a bit of planning.

Pathological smartphone use refers to incessant use of a smartphone without the ability to control the usage even when the user is aware of the harmful effects of this practice see Cha. The basic steps for performing an Failure Mode and Effects Analysis FMEA. Corrective action needed if the Detection rating is.

The RPN method then requires the analysis team to use past experience and engineering judgment to rate each potential problem according to three rating scales. Action Hierarchy a component of RCA2 that will assist teams in identifying which actions will have the strongest effect for successful and sustained system improvement. This is the list of FMEA templates inside the FMEA Studio Add-in.

FMEA AP or Action Priority is a rating method introduced in the AIAG VDA Failure Mode and Effects Analysis - FMEA Handbook. The relationship between the above mentioned parameters of FEMA. An FMEA can be performed to identify the potential failure modes for a product or process.

Take a look at our step-by-step guide for both Process FMEA and Design FMEA. The MFMEA will also track improvements through reductions in Risk Priority Number RPN. Failure modes and effects analysis also documents current knowledge and actions about the risks of failures for use in continuous improvement.

Most businesses will use an FMEA as an ongoing process to get updated through the lifetime of the productpart being monitored. Why you should try Miro for FMEA analysis. Action Priority.

As an example Figure 1 shows a sample Process FMEA PFMEA in the Automotive Industry Action Group AIAG FMEA-4 format. Free Trial Help Case Studies. The action priority method according to the new harmonized AIAG VDA FMEA method is implemented.

Download the complete toolkit with all nine tools or download individual tools as. You can switch between RPN and Action priority or show them both. Background Morphine was discovered in early 1800 by 21-year old Freidrich Wilhelm Serturner.

Action Priority In Fmea Ap In Aiag Vda Fmea Quality Engineer Stuff

Aiag Vda Fmea Action Priority Ap Fields Now Available In Qa Assistant Studio Qa Assistant Llc

0 Response to "Action Priority Fmea"

Post a Comment